Hollywood asked me to post pix of the work done at the Chicagoland Pipe Show. As you all probably know, before the actual show, there is a small pipe making seminar. Sandblasting equipment was available so I brought 4 pipes ready for sandblasting.

I managed to finish them all in the two days and ended up selling three of them. One I still have and is on my website.

This pipe had some great ring grain even when just roughly smoothed out. A promise that was kept in the end. It had quite a few pits and was going to be a blast no matter what.

This little poker I had sitting on the shelf unfinished for months. Like the above pipe I could see in the smooth wood a strong growth grain pattern. However the grain here was rather crazy and sort of ugly except for the shank which was very nice straight grain. The bottom exhibits nice and tight birds-eye. It looks WAY better blasted and once I got to work on it in earnest for the show, a little redesign and shaping made it a lot better.

This pipe was a sort of Zulu shape with the rim perpendicular to the front wall. However it sort of looked clumsy to me. So I cut down the rim and brought it more in line with the shank. I wanted the rim to be dished out and smooth to contrast with the sandblasted finish, but a rather large pit threatened to frustrate that idea. At the seminar Teddy Knudsen suggested slightly lowering only that part of the rim giving it a gentle curve. His idea worked and the pit was reduced to just a line. This pipe has a very stout, racy feel. The grain was strong and well centered, draping over the back of the bowl like a spider-web. I would not have minded keeping this one at all.

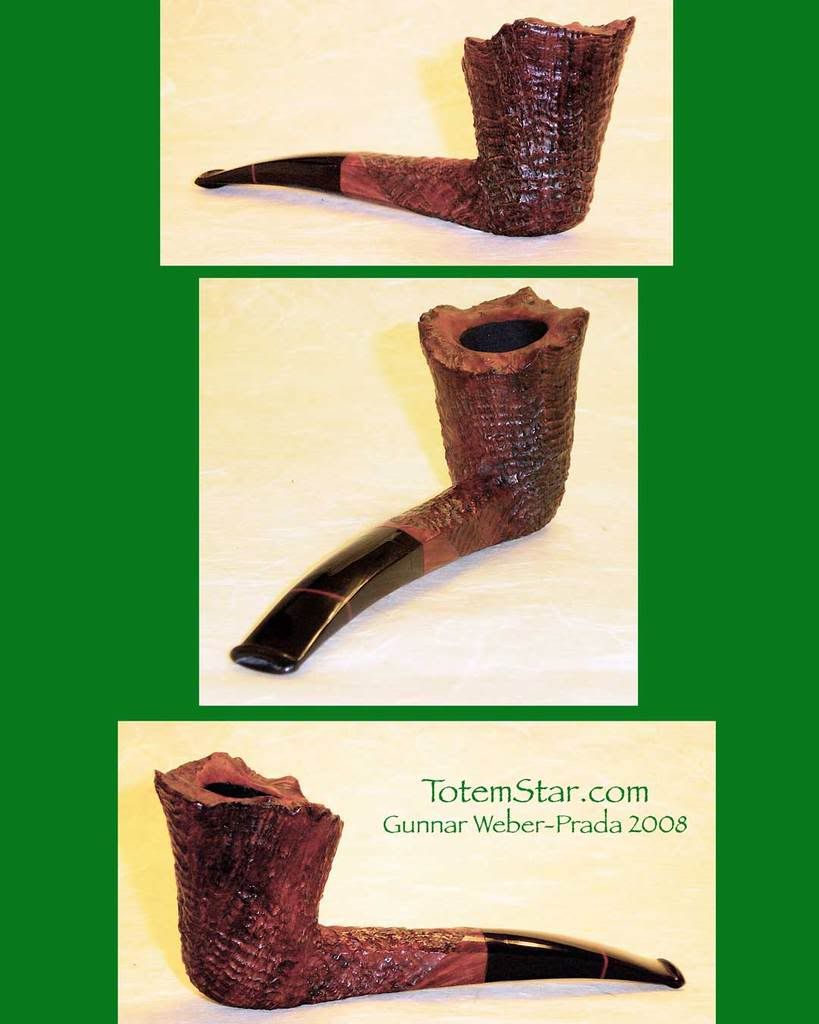

This pipe is the biggest of the group at about 6.5 inches long. This block exhibited some great straight grain, but when I was working on the shank a giant flaw appeared about 2/3s down the shank. I decided to keep it for myself or just keep it for when I might get to sandblast it. That turned out to be at Chicago about 6 months later. It's a basic, slightly stylized poker on top. I had an idea for decorating the base, which is something I like to do. This pipe was the only one were there was enough room so I went for it. Fortunately it worked because by now I was working against the clock on the last day and was not going to have enough time to redo any errors. This pipe did not sell. I was never really thrilled with the staining, so I changed it a little when I got it home, making the smooth parts much lighter. I like it now.

That's about it I think. Hope that was not too long.

Comments appreciated.