I don't know how picky bulldog aficionados are, but I recall an early thread by Tyler where he was wondering how to obtain a very narrow ring groove with a square bottom, as opposed to a U bottom obtained by using a wire, usually a guitar string.LatakiaLover wrote:The rings don't match in profile or depth (close, but not quite---the top one is shallower and more "U" shaped.)

You really need something with a right angle to it.Frank wrote:I don't know how picky bulldog aficionados are, but I recall an early thread by Tyler where he was wondering how to obtain a very narrow ring groove with a square bottom, as opposed to a U bottom obtained by using a wire, usually a guitar string.LatakiaLover wrote:The rings don't match in profile or depth (close, but not quite---the top one is shallower and more "U" shaped.)

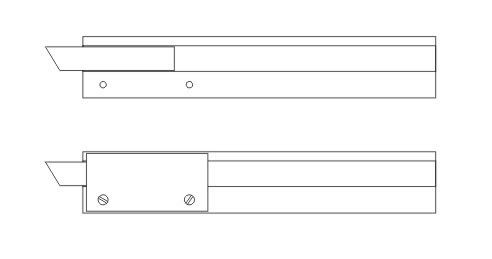

It occurred to me that one could make a tool similar to a lathe cutoff tool, using an old Xacto blade or scalpel blade with the cutting bevel ground flat. Something like this:

The rectangular steel plate that secures the blade need only be 1/16" thick. The retaing screws can be counter sunk. Allowing for the thin width of the blade, as long as the rings are more than 1/16" above the level of the shank, you should be OK.RadDavis wrote:If you try to go straight at it, that pesky shank can rap your knuckles or the tool pretty good, especially on a bent pipe.

Hey Scott,sethile wrote:I use the edge of a very small thin skew chisel too, and it is always close to hitting the shank or sliding off the edge of my rest, which is always close to hitting the shank, even when coming in at as much of an angle as I can.

This is a real limiting factor in my bulldogs in terms of how bent I can get the shank and/or how deep or far down the bowl I can go with my rings. Some kind of right angled tool would be a big help, but I've yet to see anything that would do the trick, either freehand, or in the tool holder.

Oh wow, that's a great idea, thanks, Rad! That's going to make a ton of difference! Now why didn't I think of that?RadDavis wrote:

....What you do on a metal lathe is put a tool in the tool holder so that it's parallel with the bowl rim. Scootch it up really close to the rim and use that as your tool rest. Then you are coming at the pipe from the front, and no matter how bent the shank, you can get in there with your tool.

Some people take an allen wrench, sharpen the short end of the L and use that....

I just realized that I'm big, fat dummy. When I get home tonight I'm going to go into the workshop and make myself a "right angle bulldog ring cutting tool".sethile wrote:I use the edge of a very small thin skew chisel too, and it is always close to hitting the shank or sliding off the edge of my rest, which is always close to hitting the shank, even when coming in at as much of an angle as I can.

This is a real limiting factor in my bulldogs in terms of how bent I can get the shank and/or how deep or far down the bowl I can go with my rings. Some kind of right angled tool would be a big help, but I've yet to see anything that would do the trick, either freehand, or in the tool holder.

AHA! Now that idea can be adapted to fit into a homemade tool holder. I've been trying to think of some hardened steel with a 90 deg bend. Allen wrench didn't occur to me.RadDavis wrote:Some people take an allen wrench, sharpen the short end of the L and use that.