what am i doing wrong?

what am i doing wrong?

i have purchased several 5/16" delrin rods. so, i take my trusty 5/16" mortise drill bit and place it in my drill press. with it i drill the mortise hole in stem stock. then with the exact same bit i drill the mortise hole in the stummel of the pipe i'm building. afterwards i try the delrin rod in the mortise hole in the stem stock .. slides right in, perfect fit. then i try the same delrin rod in the mortise hole in the stummel ... it won't even begin to enter the hole, the hole is too small.

i have tried this in 3 stems, and 5 stummels, all with the same results. in ebonite stem stock, or lucite stem stock, no problem at all .. perfect fit. in briar wood stummel, or cherry wood stummel, no chance of getting that delrin in the hole. even sanding on delrin, quite a bit actually, no chance of putting it in the hole.

i know full well that if i attempt to place those (now nearly finished) stummels back on the drill press and redrill, whether with the same bit, or a bigger one, nothing is going to line up the same and i'm going to screw them all up.

i'm getting very flustered here. what am i doing wrong? and how should i go about correcting, not only the ones i'm working on, but also any future attempts?

any advice would be appreciated!

i apologize if this thread is in the wrong place .. wasn't sure if i should put it in the stem work, or in the stummel forum, or somewhere else.

i have tried this in 3 stems, and 5 stummels, all with the same results. in ebonite stem stock, or lucite stem stock, no problem at all .. perfect fit. in briar wood stummel, or cherry wood stummel, no chance of getting that delrin in the hole. even sanding on delrin, quite a bit actually, no chance of putting it in the hole.

i know full well that if i attempt to place those (now nearly finished) stummels back on the drill press and redrill, whether with the same bit, or a bigger one, nothing is going to line up the same and i'm going to screw them all up.

i'm getting very flustered here. what am i doing wrong? and how should i go about correcting, not only the ones i'm working on, but also any future attempts?

any advice would be appreciated!

i apologize if this thread is in the wrong place .. wasn't sure if i should put it in the stem work, or in the stummel forum, or somewhere else.

Re: what am i doing wrong?

Ha ha, YES! Are you chamfering the end of your tenon?mathias65 wrote:i know full well that if i attempt to place those (now nearly finished) stummels back on the drill press and redrill, whether with the same bit, or a bigger one, nothing is going to line up the same and i'm going to screw them all up

viewtopic.php?f=10&t=3537

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

Re: what am i doing wrong?

Ooooh, I forgot about that post from Todd. I just made it a sticky so that it can easily be found again.

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

Re: what am i doing wrong?

Also keep in mind that ebonite and acrylic are fairly stable materials, while wood really isn't. The fact that your delrin tenon isn't fitting in the wood tells me that, perhaps, the bit is slightly worn since a dull bit can actually produce a hole that is undersized in flexible materials like wood. Maybe try a new short-length 5/16" bit? Also, what speed are you running the drill press at?

Another thing to consider is that the wood isn't actually all that dry, and when you drill the hole it shrinks around the mortis as it dries. Confusingly, the same thing can also happen if the wood is very dry, but you're working it in a very humid environment. The fibers will swell inside the mortis and change the size.

Another thing to consider is that the wood isn't actually all that dry, and when you drill the hole it shrinks around the mortis as it dries. Confusingly, the same thing can also happen if the wood is very dry, but you're working it in a very humid environment. The fibers will swell inside the mortis and change the size.

Re: what am i doing wrong?

I have had humidity problems with mortises before. If a drilled block is left for a few days on the bench and its been very humid (humidity varies greatly from day to day here) then the wood swells and the tenon can be a tight fit. For this reason as soon as a block comes off the lathe is has a tenon put in the mortise. I make up little plugs using delrin and scrap acrylic or ebonite, only about 1/2" long or so. They are useful when shaping as they help protect the face of the shank and they keep the mortise the correct diameter. I now make sure a block is never left without either the stem or one of these plugs in the mortise and my problems have gone.

Re: what am i doing wrong?

This is just an observation, but you will drill different sized holes with the same drill bit in wood and vulcanite.

Whenever I do a stem inlay, when I turn the tenon for the inlay to fit the drilled vuclanite disk, the wood inlay won't go on. When I turn it to fit the wood inlay, the vulcanite just slides on with a tiny bit of space to spare.

You may have to hunt through a few 5/16' bits to find one that will drill the wood the same size as the one you're using to drill the vulcanite and keep them seperate and marked for each application.

Or just turn an integral tenon.

Rad

Whenever I do a stem inlay, when I turn the tenon for the inlay to fit the drilled vuclanite disk, the wood inlay won't go on. When I turn it to fit the wood inlay, the vulcanite just slides on with a tiny bit of space to spare.

You may have to hunt through a few 5/16' bits to find one that will drill the wood the same size as the one you're using to drill the vulcanite and keep them seperate and marked for each application.

Or just turn an integral tenon.

Rad

Re: what am i doing wrong?

wow, now i'm totally confused!

first, Beatus, no, haven't done chamfering. not even sure what chamfering is or how one goes about it.

next, Kurt, the bit i'm using is brand new. the three stems and 5 stummels are the only 8 holes the bit has ever drilled. it is a short, mortise bit, ordered from PIMO. also, the briar wood, i'm pretty sure it's dry. the cherry wood, i know for a fact it is ... it is at least 75 years old (since the tree was turned into lumber.) and although i do live in michigan which is notorious for humidity, this is the dry season so i really don't think humidity is the problem as well. although i have no way of testing or proving it. as for the speed for the drill, i'm using the center groove of the pulleys, which i believe turns the spindle at 1390 rpm.

caskwith, if i can't get the delrin into the hole, heh, how am i going to use the delrin as a plug? and even if i could, if there is expansion, wouldn't that plug get stuck?

and finally rad, if the bits are all 5/16", why would they cut different sized holes?

any advice on how to correct this on the existing stummels that have already been drilled like this?

Re: what am i doing wrong?

You'll find that different brands of bits will drill different sized 5/16" holes. They're all marked 5/16", but some are a few thousandths larger, and some are a few thousands smaller than 5/16".mathias65 wrote:

and finally rad, if the bits are all 5/16", why would they cut different sized holes?

Rad

Re: what am i doing wrong?

Chamfering the stummel end of the tenon means cutting/sanding 90 degree edge down (~45 deg) so the tenon diameter going into the stummel starts out smaller than mortise diameter.

Although humidity affects the wood stability, it may not be a factor in your woes. Like Rad said, the same drill bit will cut a slighter different diameter hole in vulcanite than wood. It is in the nature of the materials. Wood is fussier. If you cut too fast without clearing chips, your hole will be large and the wood hole will be "glazed". If you cut slow and remove chips, you hole will likely be smaller in diameter, and those "loose" wood fibers will be "grippier" and more susceptible to changes in humidity. The vulcanite is a lot less fussy.

Although a pile of 5/16" drill bits should theoretically all cut a true 5/16", each one will be slightly different, depending on manufacturer, tolerances, and how worn down the bit is (Edit: Ohh, Rad just said that). Find one that works with your delrin diameter in wood and one that works with your delrin diameter in the vulcanite.

Although humidity affects the wood stability, it may not be a factor in your woes. Like Rad said, the same drill bit will cut a slighter different diameter hole in vulcanite than wood. It is in the nature of the materials. Wood is fussier. If you cut too fast without clearing chips, your hole will be large and the wood hole will be "glazed". If you cut slow and remove chips, you hole will likely be smaller in diameter, and those "loose" wood fibers will be "grippier" and more susceptible to changes in humidity. The vulcanite is a lot less fussy.

Although a pile of 5/16" drill bits should theoretically all cut a true 5/16", each one will be slightly different, depending on manufacturer, tolerances, and how worn down the bit is (Edit: Ohh, Rad just said that). Find one that works with your delrin diameter in wood and one that works with your delrin diameter in the vulcanite.

Re: what am i doing wrong?

so what i'm hearing is that i need to spend even more money, to buy more bits of the same size that i already have, in the hopes that one of them drills the right sized hole in wood? somehow that makes very little sense to me.

thanks for all the advice. for what it's worth i do appreciate the attempt to help.

thanks for all the advice. for what it's worth i do appreciate the attempt to help.

Re: what am i doing wrong?

There are many things in pipe making and pipe smoking that make no sense.mathias65 wrote: somehow that makes very little sense to me.

Rad

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

Re: what am i doing wrong?

That's pretty much it exactly.mathias65 wrote:so what i'm hearing is that i need to spend even more money, to buy more bits of the same size that i already have, in the hopes that one of them drills the right sized hole in wood? somehow that makes very little sense to me.

I have one bit that I use to drill 5/16" into wood, and one that I use to drill 5/16" in ebonite. If I were to use the wood bit in ebonite, I'd have a horrible and sloppy fit, and a hell of a time getting the stem and shank faces to mate up properly.

My advice, head down to your local hardware store and buy a selection of bits in 5/16" from different manufacturers. A sawbuck will get you a nice selection from most mom-n-pops. Then it's just a matter of finding the right bit.

And don't be surprised if the bit that works best for briar is still too small for the cherry.

Re: what am i doing wrong?

*sighs* i was afraid you were all going to say that. gets pretty expensive for one who's unemployed, specially when the unemployment payments just ran out.

is there any hope for saving the 5 nearly finished stummels that i currently have? the ones that the delrin currently doesn't fit in.

is there any hope for saving the 5 nearly finished stummels that i currently have? the ones that the delrin currently doesn't fit in.

Re: what am i doing wrong?

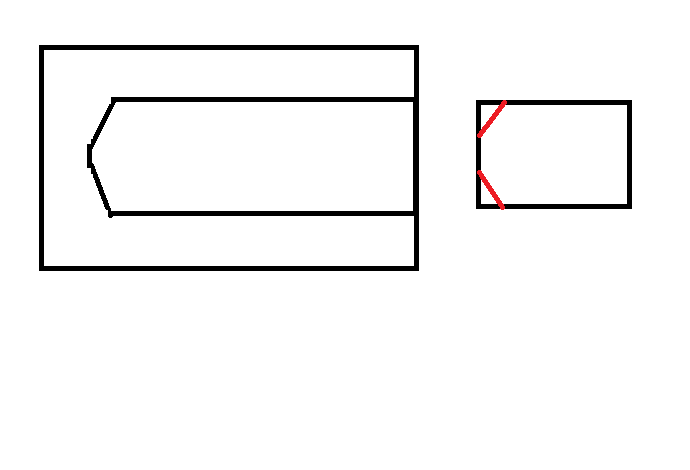

On the left is your shank, and a terrible diagram of the profile your drill bit has left in it. On the right is your delrin tenon. The red lines are where you should chamfer it to fit the profile of the mortise. Again, I apologize for the terribleness of the diagram. I found on my first pipe that the tenon wouldn't fit in my mortise and I was greatly saddened. I then chamfered it and it fit. You might want to try it first. Just to see.

- staffwalker

- Site Supporter

- Posts: 391

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: USA, texas

Re: what am i doing wrong?

I solved the problem you have by using a DeWalt 5/16 brad point to drill the Ebonite and a 5/16 Forstner bit for the wood mortise. Can't tell you who made the Forstner bit as it only has made in China stamped on it but I bought it at WoodCraft. It's slightly oversized compared to the DeWalt. bob gilbert

Re: what am i doing wrong?

thanks much. i'll take a ride to Woodcraft tomorrow to check out their Forstner bits.staffwalker wrote:I solved the problem you have by using a DeWalt 5/16 brad point to drill the Ebonite and a 5/16 Forstner bit for the wood mortise. Can't tell you who made the Forstner bit as it only has made in China stamped on it but I bought it at WoodCraft. It's slightly oversized compared to the DeWalt. bob gilbert

Re: what am i doing wrong?

Sorry for digressing, but the question to clear or not to clear confused me these days. I have drilled some mortises with unexpected slight taper, and some not, all with the same bit, so I don't think it's the bit being tapered. I haven't yet done enough experiment to find the cause, but my assumption is that by withdrawing the bit totally out of the hole when clearing chips, the outer part of the mortise is dilated a little bit due to slight swing of the stummel or the drill bit being untrue. (Please note that I am using quite short bits for the mortise to minimise wandering.) The result is that when I insert the tenon, there is no resistance at first, but the fit abruptly tightens after at least half of the tenon has already entered the mortise. That's rather annoying to me. Since I turn integral tenons after the stummel is drilled, I'm more concerned with a straight mortise than a right-size mortise. How do you drill it? Clear the chips with the bits totally going back out of the hole, or just back a little bit, or drive to the bottom all at once?kbadkar wrote:...Wood is fussier. If you cut too fast without clearing chips, your hole will be large and the wood hole will be "glazed"...

Re: what am i doing wrong?

For future, it's better to get a handful of bits and test fit before you take the stummels off the vise. For those stummels already drilled, I would hand sand the tenons. Cut a strip of sandpaper and wrap it around the tenon. Sand slightly with a twisting move. It takes a lot of patience and the tenon won't look very straight, but it's much safer than modifying the mortise.mathias65 wrote:i have purchased several 5/16" delrin rods. so, i take my trusty 5/16" mortise drill bit and place it in my drill press. with it i drill the mortise hole in stem stock. then with the exact same bit i drill the mortise hole in the stummel of the pipe i'm building. afterwards i try the delrin rod in the mortise hole in the stem stock .. slides right in, perfect fit. then i try the same delrin rod in the mortise hole in the stummel ... it won't even begin to enter the hole, the hole is too small.

i have tried this in 3 stems, and 5 stummels, all with the same results. in ebonite stem stock, or lucite stem stock, no problem at all .. perfect fit. in briar wood stummel, or cherry wood stummel, no chance of getting that delrin in the hole. even sanding on delrin, quite a bit actually, no chance of putting it in the hole.

i know full well that if i attempt to place those (now nearly finished) stummels back on the drill press and redrill, whether with the same bit, or a bigger one, nothing is going to line up the same and i'm going to screw them all up.

i'm getting very flustered here. what am i doing wrong? and how should i go about correcting, not only the ones i'm working on, but also any future attempts?

any advice would be appreciated!

i apologize if this thread is in the wrong place .. wasn't sure if i should put it in the stem work, or in the stummel forum, or somewhere else.

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

Re: what am i doing wrong?

Keep in mind, if you use a 5/16" diameter forstner bit, clearing the chips frequently is CRITICAL. They (at least the ones I've used) are too small to effectively clear chips through the body of the cutting head, so they glaze the mortis wall something fierce.

Re: what am i doing wrong?

What's the disadvantage of a glazed wall?KurtHuhn wrote:Keep in mind, if you use a 5/16" diameter forstner bit, clearing the chips frequently is CRITICAL. They (at least the ones I've used) are too small to effectively clear chips through the body of the cutting head, so they glaze the mortis wall something fierce.

And what's the difference between a forstner bit and a spiral bit as far as mortise drilling is concerned? Does the forstner bit clear chips more efficiently than a sprial bit?