Sharpening and making Lathe Tools

Sharpening and making Lathe Tools

Google comes backe with 101,000 results. From what I have read so far there seems to be different opinions on how to sharpen your tools. Some use jigs others say dont use jigs. Of course there are a bunch of specialty tools guaranteed to produce sharp edges but you know how that goes. Can anyone recomend either a web site or book on the subject? Or maybee some of you have one of those "specialty tools" that actually works, if so would you recomeend it?

Re: Sharpening and making Lathe Tools

To make tools I use a grinder with a white alu oxide wheel specialy for HSS. Depending on the shape i either grind freehand or using my precision setup, then i hone and put the final edge on using my shink waterstone sharpener, this is also used to re-sharpen tools.

I have 2 tools that do the majority of my lathe work, one is for shaping, the other for facing. Sometimes i have to make special tools for one time jobs, these are often kept only until i need the piece of HSS for another shape.

As for the actual, this is something you are best deciding for yourself as its really all down to personal preference.

I have 2 tools that do the majority of my lathe work, one is for shaping, the other for facing. Sometimes i have to make special tools for one time jobs, these are often kept only until i need the piece of HSS for another shape.

As for the actual, this is something you are best deciding for yourself as its really all down to personal preference.

-

Kettletrigger

- Posts: 34

- Joined: Sun Jun 28, 2009 1:42 am

- Location: Dana Point, CA

Re: Sharpening and making Lathe Tools

REH:

Are you grinding woodturning tools or square lathe toolbits that will be held in a toolpost of some kind?

Are you grinding woodturning tools or square lathe toolbits that will be held in a toolpost of some kind?

"The free, exploring mind of the individual human

is the most valuable thing in the world."

-John Steinbeck

is the most valuable thing in the world."

-John Steinbeck

Re: Sharpening and making Lathe Tools

I am using square tools held in a tool post. I am totally new to lathes so I am soaking up all the info I can get.

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

Re: Sharpening and making Lathe Tools

For metal lathe bits, this is the best description of the process that I've ever seen.

http://www.sherline.com/grinding.htm

http://www.sherline.com/grinding.htm

-

Kettletrigger

- Posts: 34

- Joined: Sun Jun 28, 2009 1:42 am

- Location: Dana Point, CA

Re: Sharpening and making Lathe Tools

Ahh, been there!REH wrote:I am using square tools held in a tool post. I am totally new to lathes so I am soaking up all the info I can get.

Here's a good place to start with tool grinding and general lathe info: http://www.mini-lathe.com/Mini_lathe/To ... inding.htm

That particular page is dedicated to the 7x10 minilathe commonly available from Harbor Freight, Grizzly, etc, but tool grinding practice scales just fine. When you mount the tool in the toolpost, don't forget to make sure that the height of its cutting edge is exactly (or slightly above) the lathe center line. If you're going to be cutting metal, the rake and relief angles really do matter, as well as the honed finish of the tool. If you're going to be cutting wood I can't offer specific rake and relief angles, but I'm sure that other members here can.

If cutting metal, I'd steer clear of the brazed carbide toolbits that are commonly available. They're not as sharp as HSS, are nearly impossible to hone and chip and break very easily–especially when making interrupted cuts.

"The free, exploring mind of the individual human

is the most valuable thing in the world."

-John Steinbeck

is the most valuable thing in the world."

-John Steinbeck

Re: Sharpening and making Lathe Tools

That Sherline link is pretty good if you're new to metal lathes. However, I'd recommend getting a set of holders with inserts. HSS would be better for turning briar, but HSS inserts are hard to come by. Carbide inserts will work fine for briar and stem material, but use uncoated carbide inserts.

These guys have a range of inexpensive 5 piece sets: http://www.littlemachineshop.com/produc ... uct+Search

These guys have a range of inexpensive 5 piece sets: http://www.littlemachineshop.com/produc ... uct+Search

Regards,

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Re: Sharpening and making Lathe Tools

http://www.arwarnerco.com./

HSS inserts. I've gone back and forth on this a bit. For a while I was convinced that carbide inserts were the way to go, but I find a larger nose radius of the HSS toolbits I grind myself to be more useful for cutting tenons since you want a fillet at the tenon/stem face intersection, and the larger radius can give a better surface finish if it's sharp enough. If it's dull it just creates more heat. I don't use a jig, but I do set the angle I want for the leading edge on the grinder tool rest.

I'm not sure if the OP was asking about tool bits or hand held turning tools. I don't use a jig other than the grinder tool rest for those, either. Kurt, you had some links of a guy sharpening a skew chisel or something. I don't remember it clearly, but it seemed like he had his act together, do you still have that link?

Jack

HSS inserts. I've gone back and forth on this a bit. For a while I was convinced that carbide inserts were the way to go, but I find a larger nose radius of the HSS toolbits I grind myself to be more useful for cutting tenons since you want a fillet at the tenon/stem face intersection, and the larger radius can give a better surface finish if it's sharp enough. If it's dull it just creates more heat. I don't use a jig, but I do set the angle I want for the leading edge on the grinder tool rest.

I'm not sure if the OP was asking about tool bits or hand held turning tools. I don't use a jig other than the grinder tool rest for those, either. Kurt, you had some links of a guy sharpening a skew chisel or something. I don't remember it clearly, but it seemed like he had his act together, do you still have that link?

Jack

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

Re: Sharpening and making Lathe Tools

First - thank you for that link, Jack! HSS inserts might just solve some things for me.JHowell wrote:I'm not sure if the OP was asking about tool bits or hand held turning tools. I don't use a jig other than the grinder tool rest for those, either. Kurt, you had some links of a guy sharpening a skew chisel or something. I don't remember it clearly, but it seemed like he had his act together, do you still have that link?

And here's the video that was mentioned:

http://www.youtube.com/watch?v=4m8-8MNh ... ed&search=

Mike Mahoney is a relatively famous woodturner, and in the video above he shows how to sharpen some popular woodturning chisels and gouges without the aid of jigs. I based my current procedure on his, using my belt grinder instead of bench grinder. It's really an informative video.

- ToddJohnson

- Posts: 1366

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: Nashville, TN

- Contact:

Re: Sharpening and making Lathe Tools

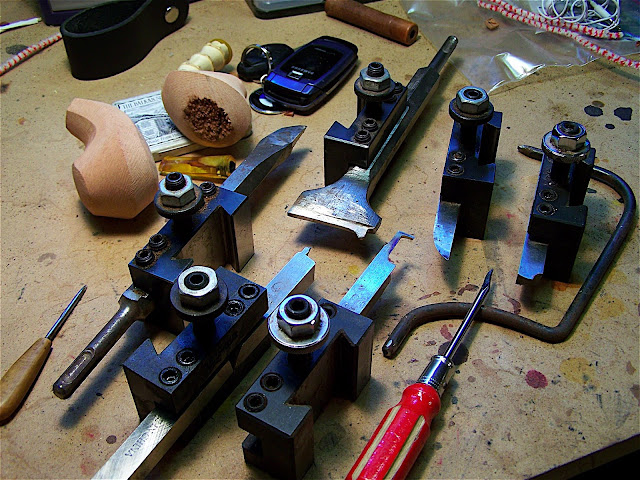

This is not a critique of the methods and formulae posted here which are all quite articulate and detailed. I'm certain that such methods are an absolute necessity for machining, thread cutting, and various other more sophisticated operations. They are not, strictly speaking, necessary for making pipes. With a simple bench grinder you can create, profile, and sharpen all the tools you will ever need to make very finely detailed high-grade pipes. I make many tools for specific tasks, and keep them very sharp with this same simple bench grinder. Here are a few shots of some tools I commonly use in my quick change tool post. All of them started as simple half inch tool blanks or, in the case of some specialized tools, air hammer bits.

TJ

TJ

Re: Sharpening and making Lathe Tools

Jack, do these guys sell to the public or only to distributors? The link I posted was just about the only retailer with HSS holders and inserts that I could find.

Thanks for that link, Kurt. I've added it to my Workshop favourites for ready reference.KurtHuhn wrote:And here's the video that was mentioned:

http://www.youtube.com/watch?v=4m8-8MNh ... ed&search=

Incidently, there's a series on PBS called "Woodturning Workshop". One of the episodes in the current series deals with sharpening a range of woodturning tools.

Last edited by Frank on Tue Sep 15, 2009 3:47 pm, edited 1 time in total.

Regards,

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Re: Sharpening and making Lathe Tools

I can only imagine what some of those things do. They look practically midevil. I am always interested in learning how to make things myself rather than buying them. It gets me into trouble sometimes and I spend way more money but I am hard headed that way. I think in this case I will purchase a set of tools and maybe start tinkering with making my own. Thanks for the help guys.

I bought a good 60 grit wheel for my grinder some time ago. Would that be sufficent or do you recomend a higher grit wheel?

Thanks for all the responses. Better than GOOGLE

I bought a good 60 grit wheel for my grinder some time ago. Would that be sufficent or do you recomend a higher grit wheel?

Thanks for all the responses. Better than GOOGLE

- ToddJohnson

- Posts: 1366

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: Nashville, TN

- Contact:

Re: Sharpening and making Lathe Tools

I use them to extract confessions out of insolent newbies. Many of the designs I got from Rad Davis.REH wrote:I can only imagine what some of those things do. They look practically midevil.

TJ

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

Re: Sharpening and making Lathe Tools

True. But I personally found that I was able to get much more consistent sharpening and performance of my lathe tools (of both kinds) once I understood the principles of both those links I posted above. Much of it isn't strictly necessary - but if you're a tinkerer like me and use your pipe tools for various other things (especially if you lathe shape any parts of a pipe on a wood lathe), it helps to understand what the tool is doing. At least in my experience. Following on that knowledge, I've been able to make all sorts of specialized toolbits for both the wood lathes and the metal lathe - some of them remarkably similar to those above.ToddJohnson wrote:They are not, strictly speaking, necessary for making pipes.

Yes, this will work fine. A higher grit wheel could cause overheating of the tool and glazing of the wheel, especially if run at 3600 RPM like most bench grinders.REH wrote:I bought a good 60 grit wheel for my grinder some time ago. Would that be sufficent or do you recomend a higher grit wheel?

Re: Sharpening and making Lathe Tools

You just took me back 25 years Kettletrigger. My Dad was an old school maintenance machinist. I was going through Machine Tool Tech at a trade school (called VoTech back in the day), and Dad swore those brazed carbide bits were the worst thing in the world. He cited exactly the same reasons you did. What he didn't know (and perhaps you don't either) is that they are designed to cut totally different than HSS tools. You need to use extremly rigid set-ups and fairly high rpm & feed rates. That avoids chipping. And you need special grinding wheels (most now use slow speed diamond wheels) to sharpen them.Kettletrigger wrote:If cutting metal, I'd steer clear of the brazed carbide toolbits that are commonly available. They're not as sharp as HSS, are nearly impossible to hone and chip and break very easily–especially when making interrupted cuts.

As to the OP:

Stick with simple, cheap HSS bits. Shape & sharpen them on any cheap bench grinder. A belt or disc sander (metal disc, not the soft ones we use for pipe shaping) will work to. Hold the tool with your bare fingers - it'll keep you from getting it too hot. Dunk it in water frequently, especially as you near the final shape you want. Try not to have any brown or blue discoleration on the finished tool. I wouldn't bother trying to hone them - unless you're good at it, you end up making the edge worse than before you started.

Also. . .It's kinda important to understand "rake angles". That's the angle behind the cutting edge of the tool. A lathe tool generally has 3 rake angles you need to be concerned with. The first link Kurt posted shows the three sides. If you're cutting wood or ebonite/acylic I would skip the part where they "break" the point.

"Cut your own wood and you warm yourself twice." - Henry Ford

Re: Sharpening and making Lathe Tools

Hot Damn, I got it down then! A year ago I asked if I could ever make high-grade pipes and was fed a bunch of esoteric artsy-fartsy BS. Now I know all I need is a simple bench grinder.ToddJohnson wrote:With a simple bench grinder you can create, profile, and sharpen all the tools you will ever need to make very finely detailed high-grade pipes.

"Cut your own wood and you warm yourself twice." - Henry Ford

Re: Sharpening and making Lathe Tools

I used a belt grinder and 1/2' hss blanks. In retrospect I should have used the disc side, because they are cheaper to replace. I went through 2 belts to profile 3 tips.

- SimeonTurner

- Site Supporter

- Posts: 750

- Joined: Wed Dec 24, 2008 7:46 pm

- Location: Denver, Colorado

- Contact:

Re: Sharpening and making Lathe Tools

careful Fred! I hear Todd has a significant investment in the bench grinder industry, so his opinion is actually a biased attempt at raising his stock. There are actually lots of other tools you will need. If you will send me your credit card info, or buy stock in my company, I'll send you all of them by mail.FredS wrote:Hot Damn, I got it down then! A year ago I asked if I could ever make high-grade pipes and was fed a bunch of esoteric artsy-fartsy BS. Now I know all I need is a simple bench grinder.ToddJohnson wrote:With a simple bench grinder you can create, profile, and sharpen all the tools you will ever need to make very finely detailed high-grade pipes.

"It is noble to be good; it is still nobler to teach others to be good - and less trouble."

Turner Pipes Website:

http://www.turnerpipes.com

Of Briar and Ashes:

http://turnerpipes.wordpress.com

Turner Pipes Website:

http://www.turnerpipes.com

Of Briar and Ashes:

http://turnerpipes.wordpress.com

-

pierredekat

Re: Sharpening and making Lathe Tools

I've found it easier to keep the various diameters of a stem concentric by inserting a live center in the draft hole as early-on as possible.

But turning a tenon up against a live center will force you to really study the angles of your live center, toolpost, etc.

After much experimentation, I eventually settled on a bit similar to this one:

Except that mine has about a .030 inch flat on the point -- at just the right angle -- that gives me a much smoother surface finish on the tenon, using my current equipment, that is.

And fortunately, this same bit has worked quite nicely for general rough-cutting, as well.

Anywho, start with Kurt's link there, and then, when you have the basics, start tweaking things to suit your needs.

But turning a tenon up against a live center will force you to really study the angles of your live center, toolpost, etc.

After much experimentation, I eventually settled on a bit similar to this one:

Except that mine has about a .030 inch flat on the point -- at just the right angle -- that gives me a much smoother surface finish on the tenon, using my current equipment, that is.

And fortunately, this same bit has worked quite nicely for general rough-cutting, as well.

Anywho, start with Kurt's link there, and then, when you have the basics, start tweaking things to suit your needs.

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

Re: Sharpening and making Lathe Tools

(whispering) Go with Ceramic belts, they're expensive, but one can profile about a two dozen HSS 1/2" tool bits.Ryan wrote:I used a belt grinder and 1/2' hss blanks. In retrospect I should have used the disc side, because they are cheaper to replace. I went through 2 belts to profile 3 tips.