Yeah she's a cutie alright. She just turned 4 years old. I have recently replaced that picture with some conceptual drawings of pipes. She noticed and started to whine "Awwwwww where is my picture??????"

I told her it was still in the shop but just moved but she insists that it be in that spot fromt and center lol.

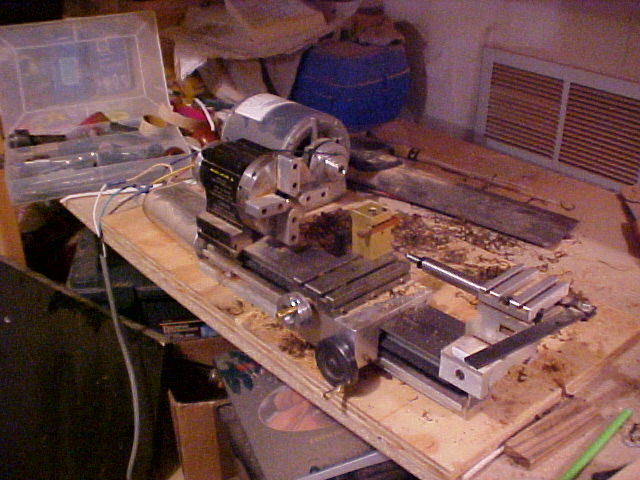

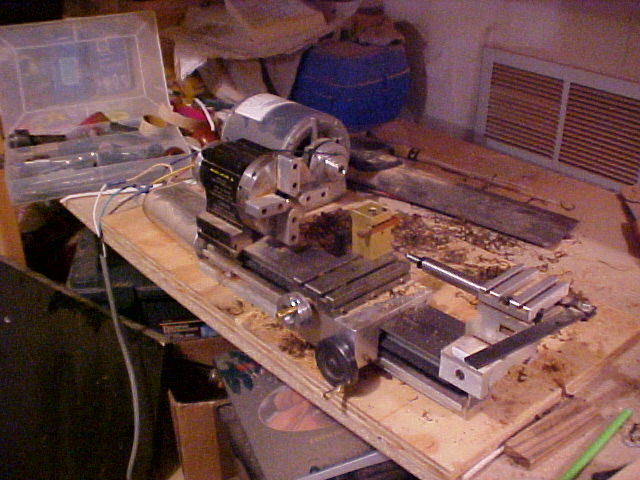

I was talking to Munkey about the worktable in the CPS chat room. So here is the 411 on that. (If anyone is interested)

I was told by a very wise pipe carver

that you need a very stable and heavy table if you are going to turn blocks on a lathe so.... that is what I shot for (Anything worth building is worth over-building right?)

The work surface is 22" x 48" and constructed of 2 layers of 3/4" particle board that are glued together with "Liquid Nails" subflooring glue. That is then glued and screwed with 3" wood screws to a 2 x 4 frame.

The legs are (2) 2 x 4 's glued together with the Liquid nails and screwed together with 3" screws as well. They are in turn glued and screwed to the top just inside the frame.

There is a 2' x 4' piece 3/4" of particle board attached to the back acting as both a brace and a back splash for the bottom shelf. That bottom shelf (not in the picuture) is built with 2 layers of 3/4" board just like the worktop.

The entire thing is put together with 3" wood screws and anywhere wood is in contact with each other is glued with the sub flooring glue. The glue comes in a chalk like tube so I then went and "cauked" every seam with the leftovers. I built the bottom shelf thick so that I could store (3) 40 lb bags of water softener salt on it for added wieght. I do not know how heavy the whole thing it. I would imagine, with the salt and lathe, at least 400 pounds.

I can turn an eccentric block on the lathe at the highest speed (3900 rpm or so) with nothing but vibration. ( I do have to make sure anything not bolted to the tabletop is removed or it will walk all over the place) The lathe, of course, is bolted to the table top.

I thought briefly about putting threaded rods in the concrete floor of my garage and bolting the whole thing to the floor but thought that was a bit extreme.