Page 1 of 2

applying sandpaper to Rudat Design french wheel

Posted: Thu Sep 29, 2022 12:44 pm

by jazoni

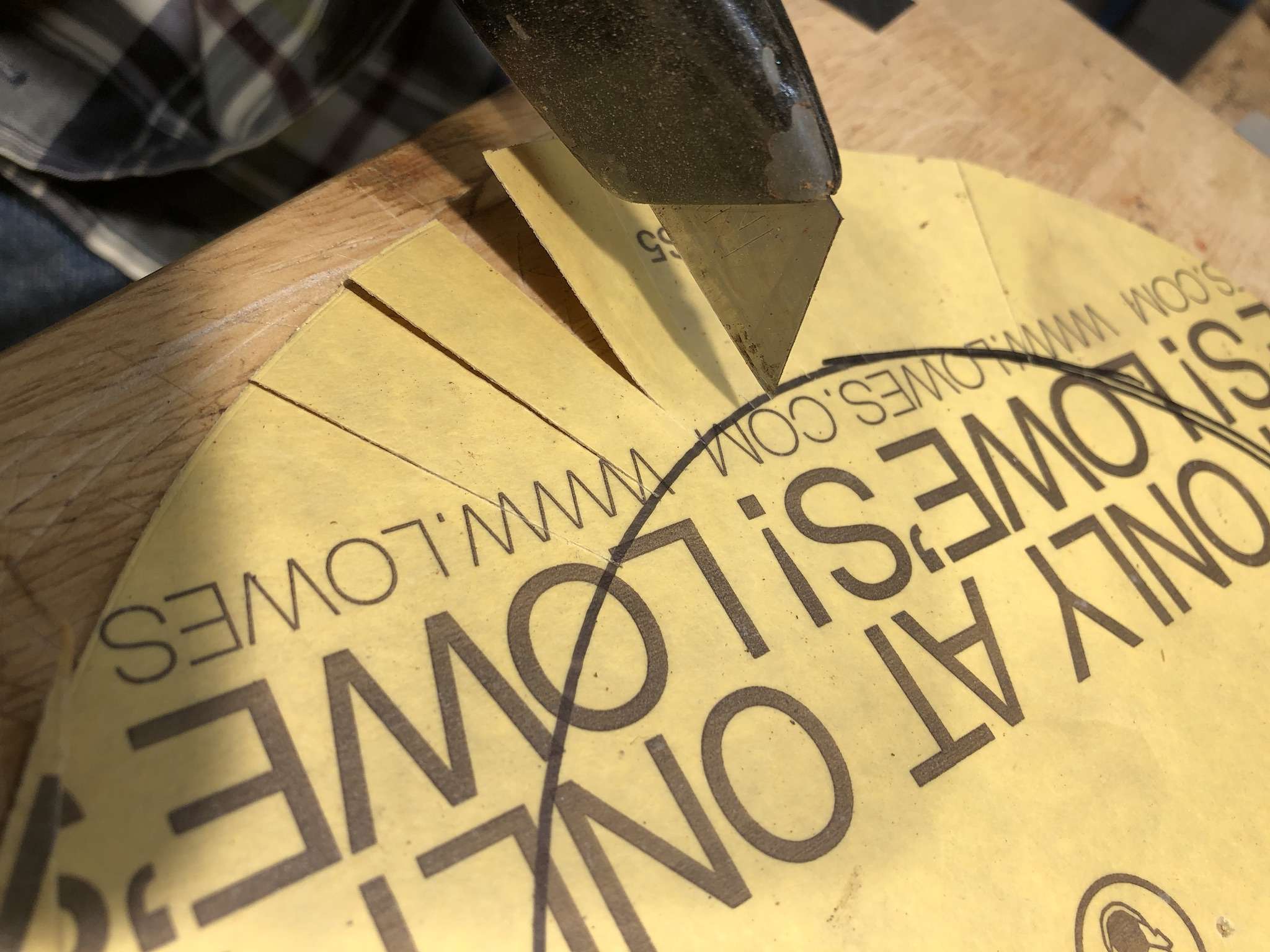

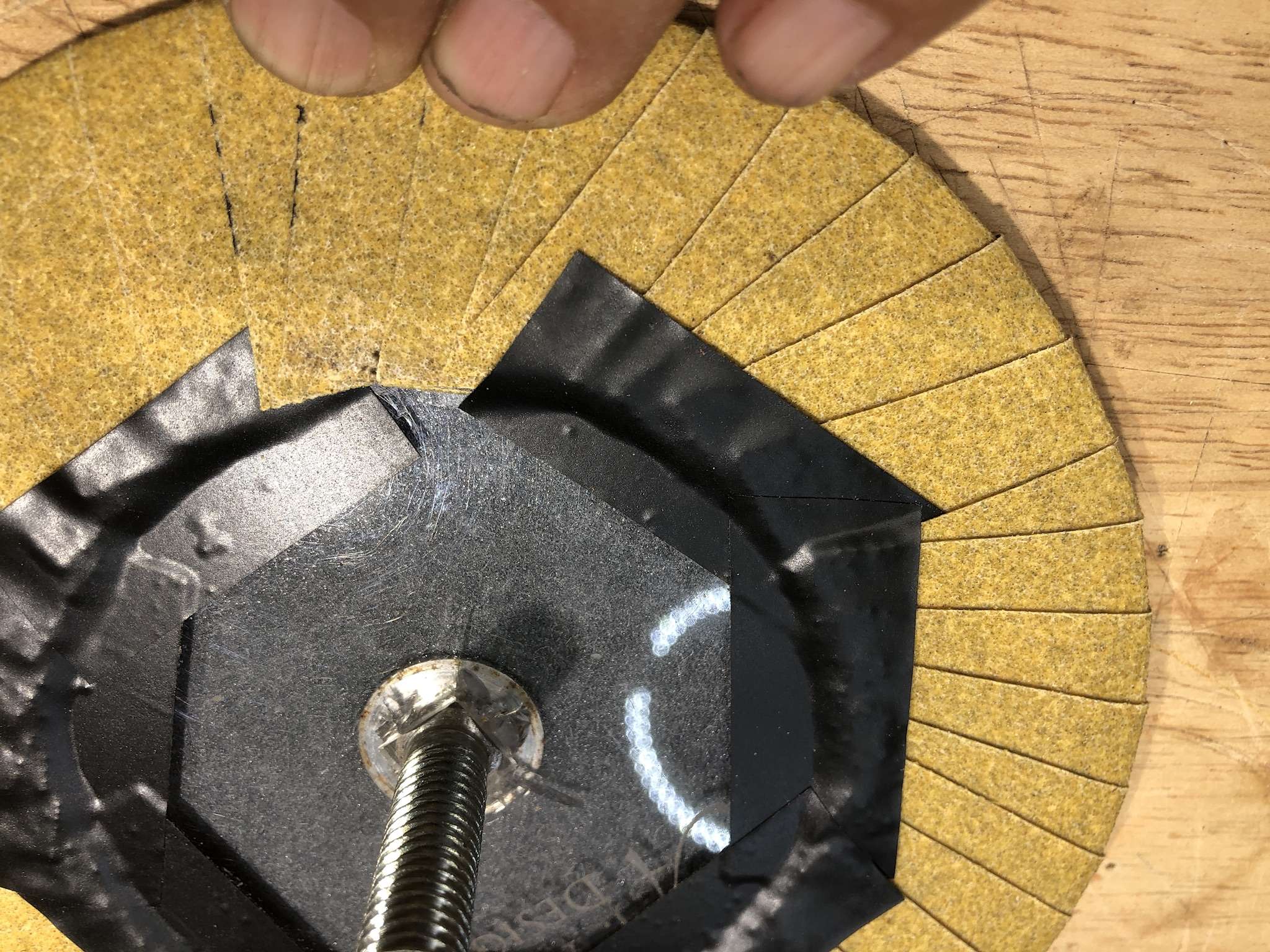

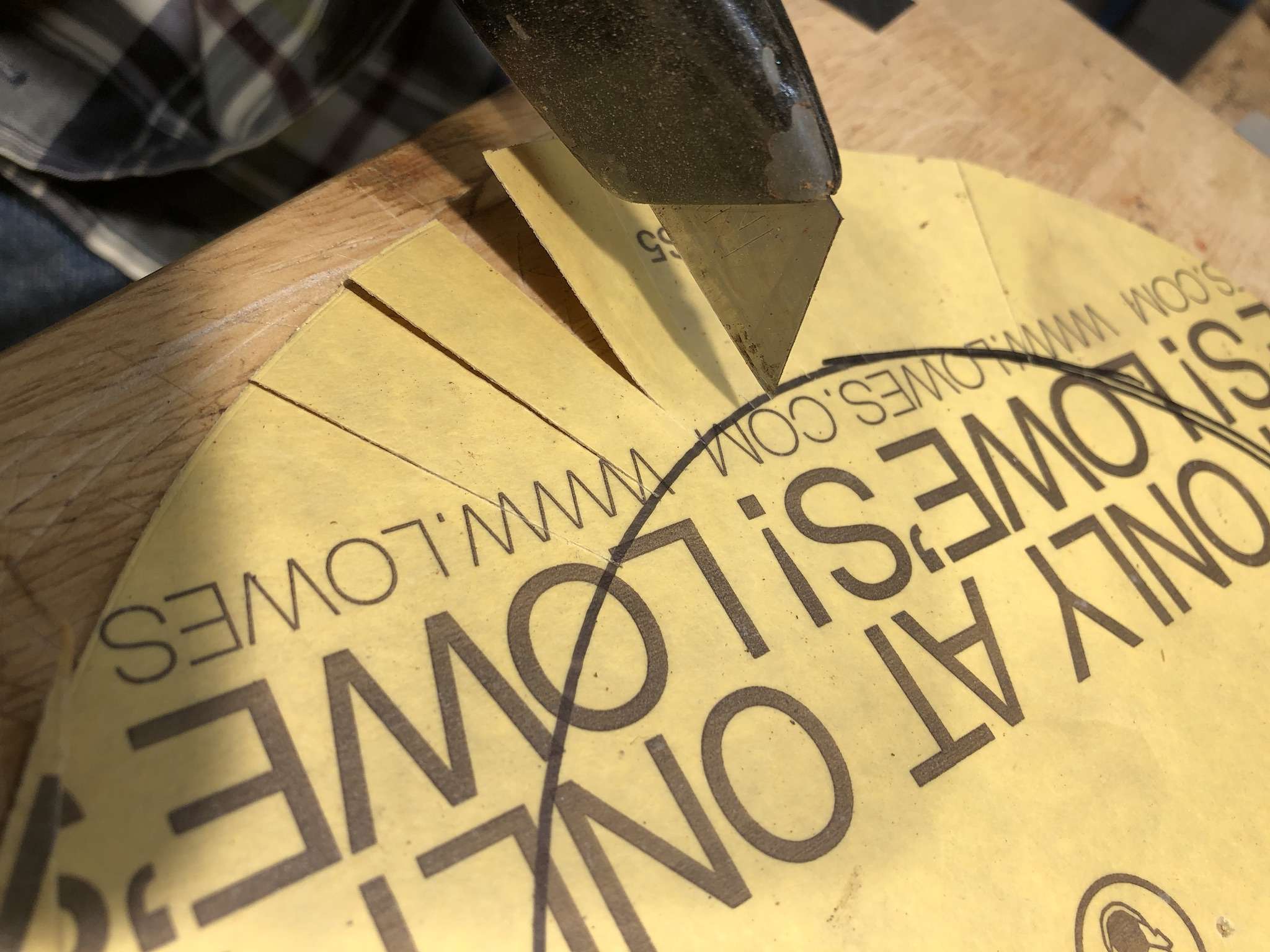

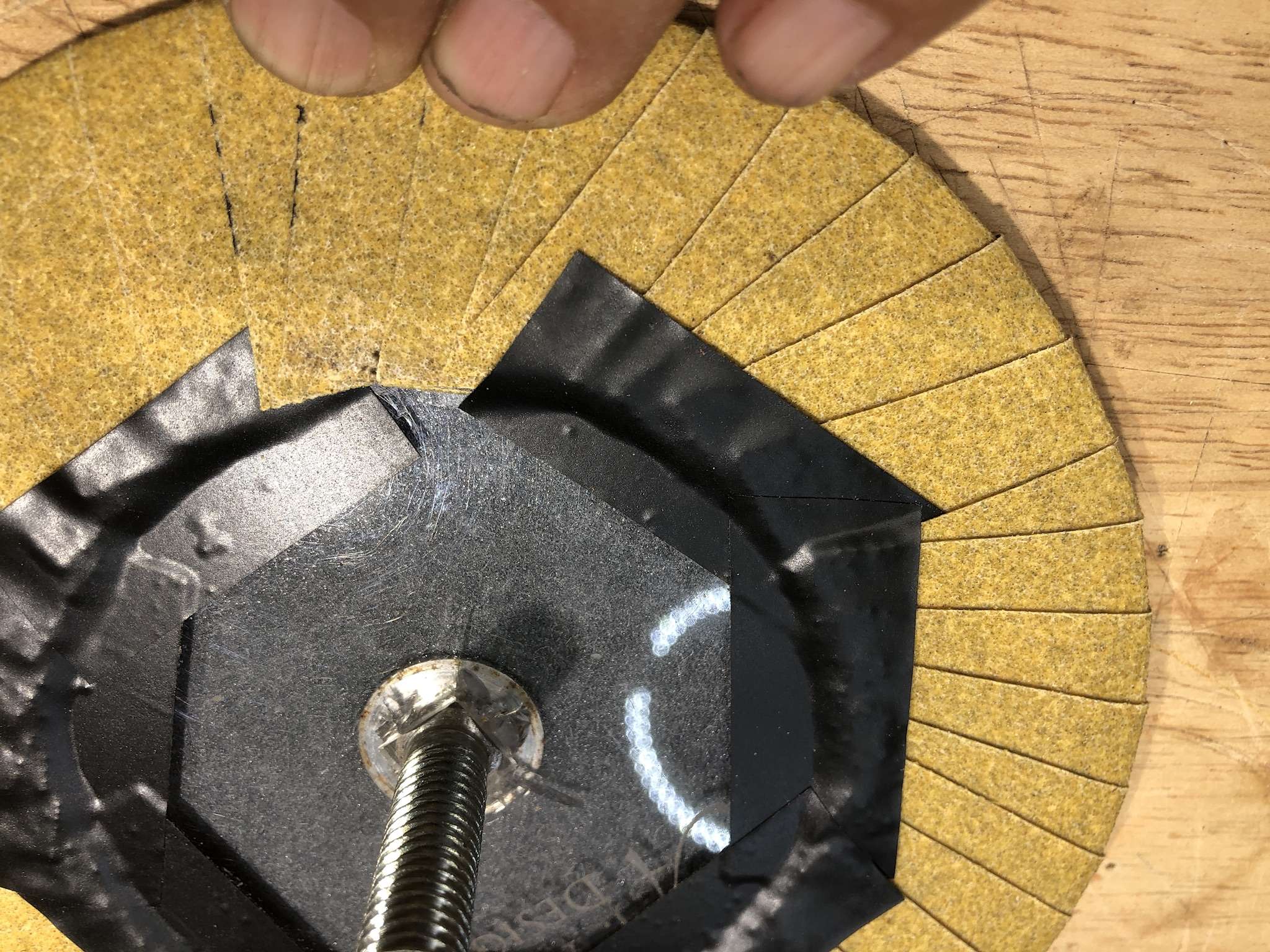

I bought the french wheel that Vermont Freehand sells (Rudat Design) and I can't for the life of me get the sandpaper to not pucker. Is there something I'm missing? Is puckering just inevitable because of the curve of the pad? This is what it ends up looking like:

https://imgur.com/a/0NSC52e

I'm cutting my own sandpaper. making slits all the way around like you do with a circle, and duck taping each flap down. Not sure if I'm cutting the paper wrong or what.

Re: applying sandpaper to Rudat Design french wheel

Posted: Thu Sep 29, 2022 3:53 pm

by LatakiaLover

Yeah, it's a fussy business.

Try cutting more flaps, pull tighter when folding the flaps over, and using masking tape instead of duct tape to allow re-positioning when needed.

Also, the garnet paper you are using is probably the worst possible type to put on a wheel. The backing is thin and delicate and curls with age and humidity.

What's known as "auto body" sandpaper is much easier to handle. See if you can find a brand called Black Ice.

Re: applying sandpaper to Rudat Design french wheel

Posted: Thu Sep 29, 2022 4:06 pm

by jazoni

Good point about the sandpaper. I'll check that out! I did figure out a way to get it to lay flat by cutting the flaps longer more toward the center of the paper, but that leaves me with the slits from the flaps wrapping around the edge of the wheel, so would need something stronger so those don't tear.

Re: applying sandpaper to Rudat Design french wheel

Posted: Thu Sep 29, 2022 4:19 pm

by DocAitch

My wheel is a J Alan design with a flatter face and I can see the difficulty getting a good surface for the face of the Rudat wheel. I can only suggest that you cut your paper to the that bevel on the face OR get a J Alan design wheel.

I use a procedure similar to George’s but tape more than 1 flap at a time and I use electrician’s tape. I also cut my flaps about every 1/2 inch.

I also want to emphasize that if you are using a counter clockwise turning wheel, the direction of folding over is in a clockwise direction. This presents a tangential surface to the work rather than an edge.

I also just use what ever paper comes to hand.

DocAitch

Re: applying sandpaper to Rudat Design french wheel

Posted: Fri Sep 30, 2022 11:35 am

by jazoni

Yeah that's what I ended up doing is cutting the flaps to the inmost beveled edge. everything laid flat and worked good. I like the convex-ness of the Rudat one because it allows you to sand in a way you can't with the flatter design but the J. Alan ones are super nice too. i also use a little 5" sanding pad from home depot that I chuck up in the lathe with hook and loop sandpaper and that works pretty great too.

Re: applying sandpaper to Rudat Design french wheel

Posted: Fri Sep 30, 2022 11:40 am

by DocAitch

You can also make your own J Alan design wheel. PM me and I can send a pictorial.

DocAitch

Re: applying sandpaper to Rudat Design french wheel

Posted: Sun Oct 02, 2022 11:18 am

by caskwith

Pfft, French wheels.

Re: applying sandpaper to Rudat Design french wheel

Posted: Sun Oct 02, 2022 2:04 pm

by LatakiaLover

caskwith wrote: ↑Sun Oct 02, 2022 11:18 am

Pfft, French wheels.

Would you like 'em better if they were called English wheels?

Re: applying sandpaper to Rudat Design french wheel

Posted: Sun Oct 02, 2022 10:28 pm

by dogcatcher

Odd man out. Go to harbor freight, find the 9 inch angle grinder then with a 9" backing pad for sanding discs using PSA Sanding disc's. Search on line for a speed controller for angle grinders.

Put it altogether and create a mount for it. Buy discs from Klingspor woodworking. End result, CHEAP and it WORKS.

Re: applying sandpaper to Rudat Design french wheel

Posted: Mon Oct 03, 2022 2:09 am

by Massis

LatakiaLover wrote: ↑Sun Oct 02, 2022 2:04 pm

caskwith wrote: ↑Sun Oct 02, 2022 11:18 am

Pfft, French wheels.

Would you like 'em better if they were called English wheels?

Bloody French, first they take my fries, then they take Chris' wheels.

Re: applying sandpaper to Rudat Design french wheel

Posted: Mon Oct 03, 2022 4:55 am

by caskwith

Re: applying sandpaper to Rudat Design french wheel

Posted: Mon Oct 03, 2022 4:59 am

by caskwith

dogcatcher wrote: ↑Sun Oct 02, 2022 10:28 pm

Odd man out. Go to harbor freight, find the 9 inch angle grinder then with a 9" backing pad for sanding discs using PSA Sanding disc's. Search on line for a speed controller for angle grinders.

Put it altogether and create a mount for it. Buy discs from Klingspor woodworking. End result, CHEAP and it WORKS.

DO you currently use this method? I can't imagine it working very well myself based on my experience with angle grinders.

Re: applying sandpaper to Rudat Design french wheel

Posted: Mon Oct 03, 2022 9:33 pm

by LatakiaLover

dogcatcher wrote: ↑Sun Oct 02, 2022 10:28 pm

Odd man out. Go to harbor freight, find the 9 inch angle grinder then with a 9" backing pad for sanding discs using PSA Sanding disc's. Search on line for a speed controller for angle grinders.

Put it altogether and create a mount for it. Buy discs from Klingspor woodworking. End result, CHEAP and it WORKS.

Hm.

Angle grinders have low torque by design---they work via the momentum of 10K rpm---and slowing one to pipe shop speed will cause it to heat excessively when put under load.

In addition, any type of speed controller that accomplishes the task by reducing voltage light-dimmer-style will trash the motor quickly. And

non-dimmer type boxes are spendy.

I gotta go with Chris on this. Have you actually done what you describe, or just put it together in your mind? (so to speak)

Re: applying sandpaper to Rudat Design french wheel

Posted: Mon Oct 03, 2022 9:52 pm

by dogcatcher

I thought the same, but a friend used one to power a woold lathe using a router speed controller. I did the same. I have, the HF are cheap ones that will accept a router speed controller. The angle grinder I have uses replaceable brushes. Not the same as my higher dollar Makita angle grinder.

I also have added a 9" angle grinder backing plate to an industrial sewing machine servo motor.

I am not a pipemaker, I use to use these to power carve and to finish out chainsaw carvings. The power carving is shaping of gunstocks and custom slingbows. A slingbow is a slingshot designed to shoot arrows

I came across this forum while searching how to dye muzzleloader maple stocks when searching for leather dye. My angle grinder system improved when I read about the French wheel.

Re: applying sandpaper to Rudat Design french wheel

Posted: Tue Oct 04, 2022 3:08 am

by caskwith

Well I stand corrected.

For pipe making work I have found the best option for me is the cheapest 6" bench grinder I can buy. They cost me about £20, the current one has been running for about 3 years I think. Speed is 3000rpm which I use for sanding discs from 3" to 6". If you are going to use a 9" disc then I think a 1500rpm motor might be better. I know some prefer a 1500rpm motor in general.

I have used speed adjustable setups in the past and I will admit it's nice to be able to slow it down for detail shaping but after a while I got too lazy to change the speed and learned to work everything at 3000rpm.

Re: applying sandpaper to Rudat Design french wheel

Posted: Tue Oct 04, 2022 8:01 am

by LatakiaLover

Interesting.

Sounds like the entire situation depends on the exact models of things used in a certain combination.

If it works, it works, in other words; and if it doesn't, well... it didn't. lol

My shop has two VFDs---one on a belt grinder, the other on a bench motor---and while spendy, those things are The Shit. Zero to max rpm by turning a dial, and never a worry.

You definitely learn to use whatever you have. With my hands getting old I definitely appreciate electrons doing a lot of the work.

Re: applying sandpaper to Rudat Design french wheel

Posted: Tue Oct 04, 2022 8:23 am

by dogcatcher

Another person's rig of an angle grinder and router speed controller.

https://youtu.be/mDT6pckv95w

Re: applying sandpaper to Rudat Design french wheel

Posted: Tue Oct 04, 2022 2:07 pm

by caskwith

LatakiaLover wrote: ↑Tue Oct 04, 2022 8:01 am

Interesting.

Sounds like the entire situation depends on the exact models of things used in a certain combination.

If it works, it works, in other words; and if it doesn't, well... it didn't. lol

My shop has two VFDs---one on a belt grinder, the other on a bench motor---and while spendy, those things are The Shit. Zero to max rpm by turning a dial, and never a worry.

You definitely learn to use whatever you have. With my hands getting old I definitely appreciate electrons doing a lot of the work.

My first sanding motor had a full range speed control from (a usable) low of maybe 100rpm up to a top speed of 3600rpm I think, the more I used it and the better I got, the more I was just turning it up to full speed and leaving it there almost all the time. When that motor died I tried something else with variable speed and ended up using it at full speed all the time because it was more awkward to adjust. After that I just used 3000rpm for everything it doesn't bother me now.

I also started cutting back on the power of the motor. My current sanding motor is only 200W (it might be 250W, I can't be arsed to go check), so about 1/3rd HP and I find it plenty powerful enough for my needs and keeps the electricity bill low.

Re: applying sandpaper to Rudat Design french wheel

Posted: Tue Oct 04, 2022 6:36 pm

by LatakiaLover

Fun stuff.

In my case I've pushed the boundaries at each end. Coarser and faster when doing bulk material removal; and slowing to a crawl with 220 grit to see how close I can get to finished dimensions with a machine before hand-tooling it.

For some reason this discussion reminds me of all the slack belt sander excitement 7-8 years ago. One of the famous Scand guys was filmed using a six foot tall homemade rig and suddenly every carver wanted one. A guy even took build orders at Chicago for a couple years for a machine he designed, with a demo model at his side.

Turns out that NO ONE could duplicate the results of the Scand guy, though. He'd just learned to shape that way from day one, had a lifetime of practice, and made it look easy. Minimal motion, smooth as butter, no hesitation. Like a master musician.

The longer you're at this game the more you realize that the "right" tool for a task is whatever works best for YOU.

Re: applying sandpaper to Rudat Design french wheel

Posted: Wed Oct 05, 2022 7:02 am

by caskwith

Absolutely.

I tried a slack belt sander at Mimmo's shop and while I could see there were some useful applications, I preferred the methods I was already using. If I made more smooth pipes though I would build one, a really slow, flexible, long belt is superb for sanding bowls as you can follow the curves in a way that only hand sanding can really beat. Since I mostly make blasts though it's just not needed, discs and a little file work cover my needs.