Page 1 of 1

Disc Sander

Posted: Sun Dec 06, 2015 10:43 am

by hutchpipes

Hey folks. I inherited and old bench grinder that I am attempting to turn into a disc sander for shaping. It has a 1/2 threaded shaft. Anyone know of a really good way to make this work?!

Re: Disc Sander

Posted: Sun Dec 06, 2015 12:08 pm

by PremalChheda

Does it work? If not, you may be better off going with a motor that has a 5/8" shaft so you can just buy existing arbors.

If it works, then you can either buy or get made arbors that will attach your sanding discs.

Re: Disc Sander

Posted: Sun Dec 06, 2015 1:02 pm

by hutchpipes

Definitely works! Hate to buy a motor when I have one. Who makes a 1/2 arbors? I haven't bought any sanding discs yet. Been doing all shaping on a 1x30 belt. Any suggestions on arbors or discs?

Re: Disc Sander

Posted: Sun Dec 06, 2015 4:42 pm

by PremalChheda

hutchpipes wrote:Definitely works! Hate to buy a motor when I have one. Who makes a 1/2 arbors? I haven't bought any sanding discs yet. Been doing all shaping on a 1x30 belt. Any suggestions on arbors or discs?

Depends on what type of sanding disc you want to attach, and how you want to attach it.

Do some searches and find what you need.

Examples:

https://www.google.com/search?q=1%2F2+i ... aded+arbor

https://www.google.com/search?q=1%2F2+i ... inch+arbor

etc..

I would make or get custom arbors made for each of the discs I wanted to use. That way you could just thread them on and off quickly.

Re: Disc Sander

Posted: Sun Dec 06, 2015 6:03 pm

by LatakiaLover

Scroll down to 1/2" work arbor (R):

http://www.jhlowe.com/machine_parts.htm

Orient your motor so that you'll be using the righthand-threaded shaft (it's best to avoid messing with lefthand threads unless necessary).

Once you have such an arbor fitted, any sanding disc or buff with a 3/8" coarse-thread bolt/shaft can be swapped in and out as needed.

PS --

DO NOT mess with sanding discs until you have a dust collection method hooked up. You'll be tempted to "tough it out", but that's a very serious and potentially life-changing mistake. 1) Once fine particulates get into your lungs, they are there

forever. There is no un-do button. 2) Besides mechanically reducing lung capacity and efficiency, many substances cause inflammation & etc. all the way up to cancer.

Re: Disc Sander

Posted: Sun Dec 06, 2015 9:41 pm

by sandahlpipe

You can also get or make arbor adapters from 1/2" to 5/8"

If you're not able to get dust collection, you can use a dust mask in the interim. A shop vac does ok for a while, but isn't as efficient as proper dust collection.

Most grinder motors operate at 3600rpm. This is a tad fast for fine work. 1750 is more suitable. I've gotten a couple of furnace blower motors off craigslist for $10 that have the proper speed, but they spun the wrong way for the threads in my bolt. Some motors can be had for cheap that will be slower speed and I think you'll have an easier time going that route. If you're ready to spend the money, get a VFD and a 3 phase motor from automation direct. It's a world of difference from the harbor freight one that I now use as a backup.

Re: Disc Sander

Posted: Thu Dec 10, 2015 11:31 am

by Charl

Don't sweat too much about speed and power at this stage. A motor with a disc attached is what you need, so use what you have.

Re: Disc Sander

Posted: Thu Dec 10, 2015 12:26 pm

by andrew

I second the dust collection comment. I toughed it out. It was a bad idea. Just buy one arbor that will thread on to the shaft. Then you can use 3/8" coarse thread for your attachments.

Re: Disc Sander

Posted: Tue Dec 22, 2015 10:30 am

by DocAitch

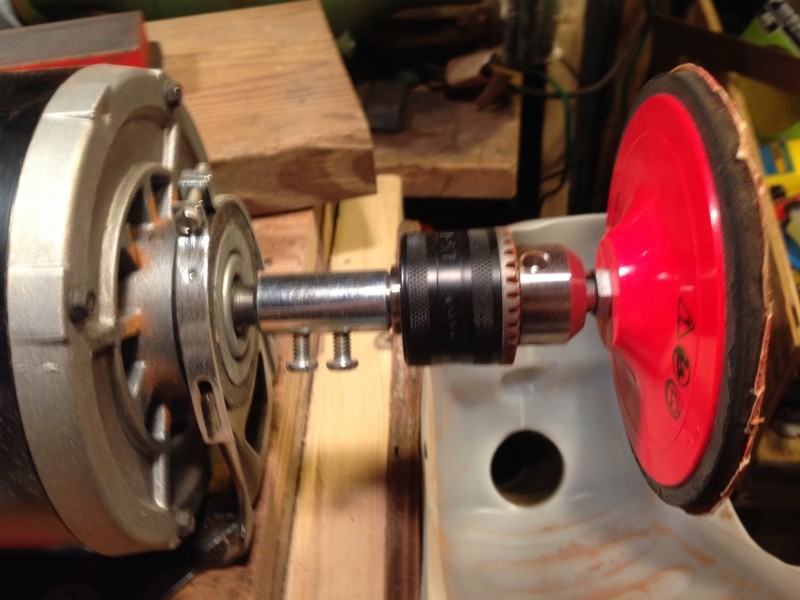

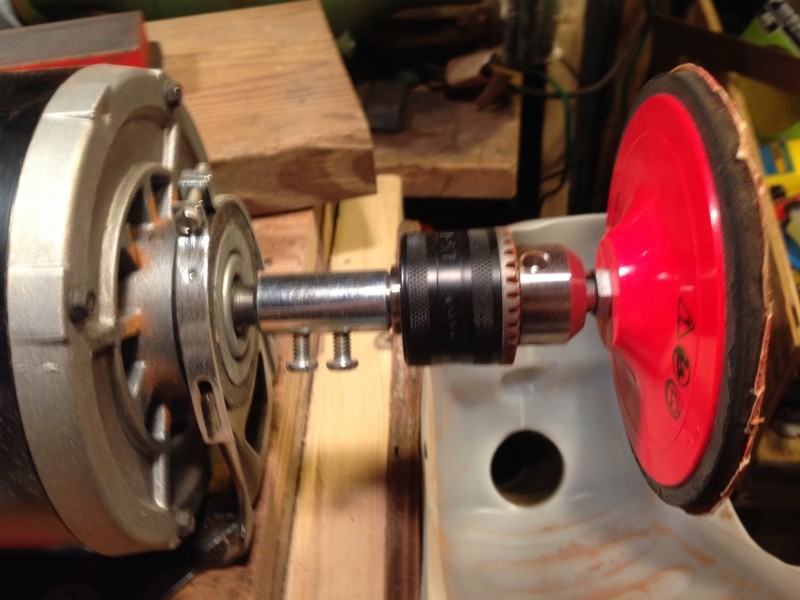

A Jacobs drill chuck will probably thread onto that shaft, then you can use any of dozens of sanding discs made for a hand drill.( I got mine from Amazon 1/2"x20 less than $ 15 )

Generally (at least on modern motors), there is a diagram of the electrical connections on the information plate of the motor. Mine, which are new , have the statement "to reverse shaft rotation, switch red and black wires". Both of my motors ran clockwise out of the box and unscrewed my chuck, but reversing the rotation was very quick and easy.

I also use a shop vac with kitty litter containers to make my sanding hoods. Works well, although the shop vac is noisy.I posted photos of this in the pipe making section of the Pipe Smokers forums.

DocAitch

Re: Disc Sander

Posted: Wed Dec 23, 2015 8:16 pm

by DocAitch

In follow up to the previous reply. If your shaft is 1/2" x 20, this Jacobs chuck will fit. there are other size chucks available.

I shortened the threaded part of the arbor to reduce chance of wobble.

This will work even though it is threaded.

DocAitch

Re: Disc Sander

Posted: Sat Dec 26, 2015 12:06 am

by dogcatcher

The threads look like 1/2-20.go to a hardware store and ask for a nut that is 1/2-20TPI. Take it home and try it, I say this because it could be bastard sized threads. If the 1/2-20TPI nut works by a drill chuck like this one.

http://www.amazon.com/Metal-3-16mm-Capa ... rill+chuck

If the nut fits the chuck should screw onto the shaft without having to buy any adapters

Any good industrial supplier will have them or be able to order one. Then follow the instructions on the above post by DocAitch.

Re: Disc Sander

Posted: Sat Dec 26, 2015 11:42 am

by caskwith

1/2-20 is the standard thread used on cordless drill chucks, so you could take the chuck off your cordless drill and try that just as a test.

Re: Disc Sander

Posted: Mon Jan 04, 2016 11:29 pm

by DocAitch

Any progress on this?

DocAitch