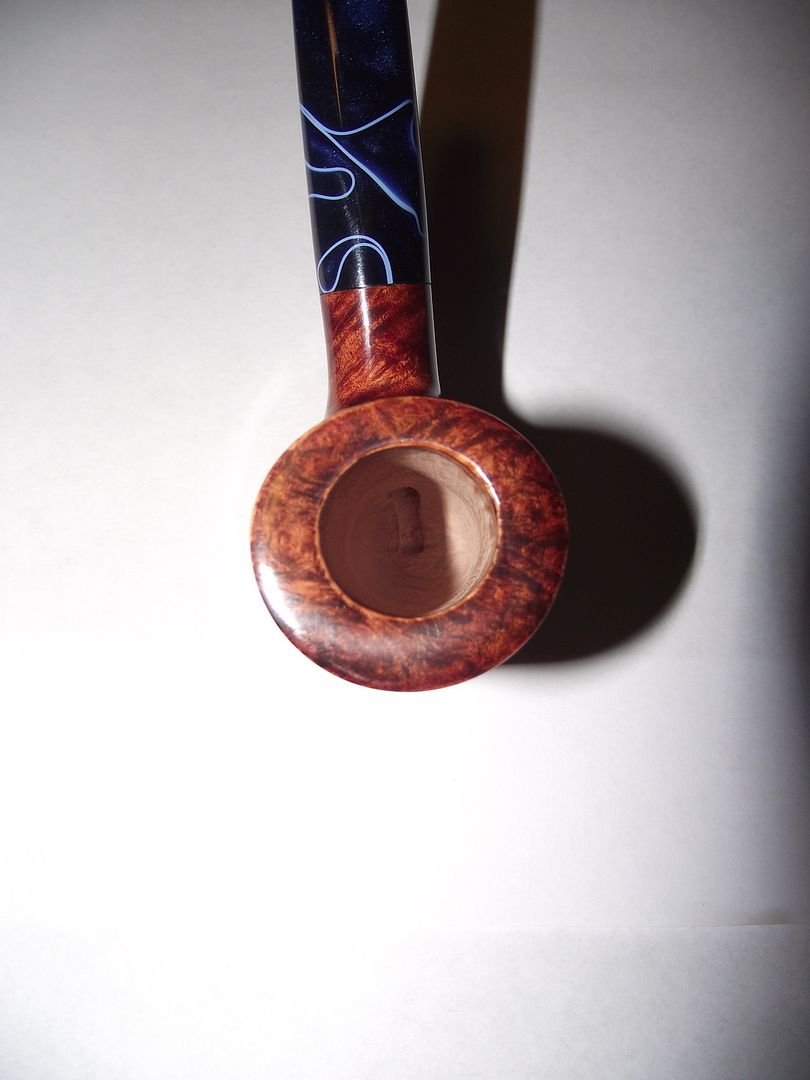

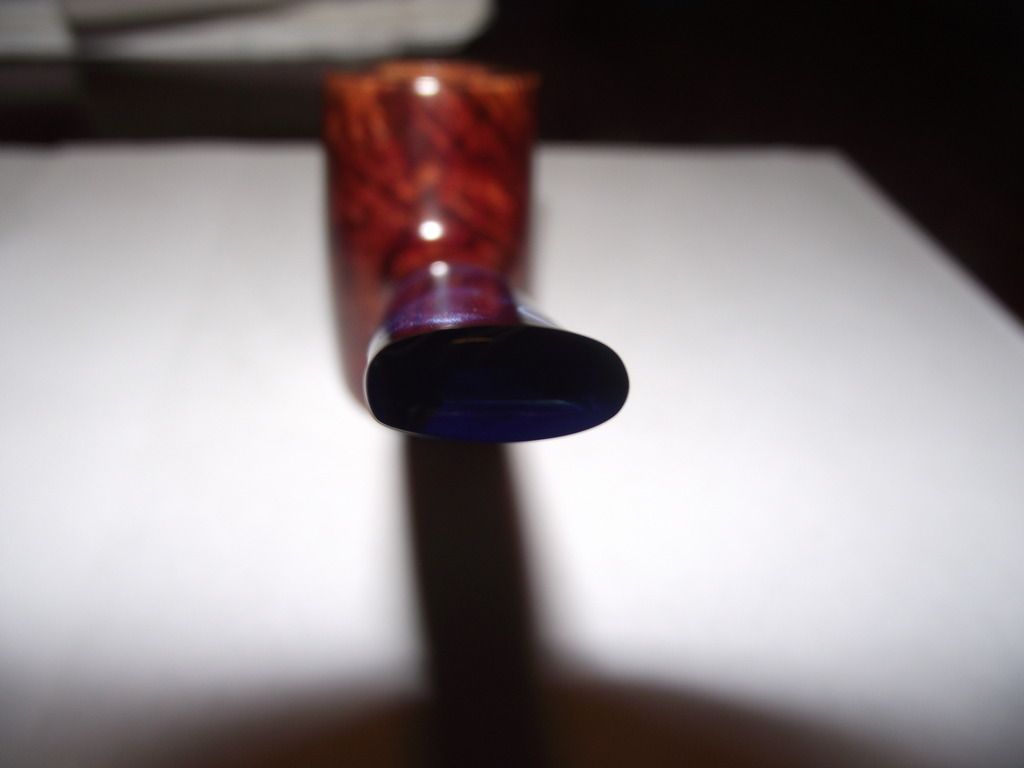

I'm having issues keeping everything square. I am also having some problems keeping things round on my sanding wheel. There is a tiny gap on one side where the tenon meets the shank as my drill press must have tilted a bit when I was facing them. The shank flares out slightly, as it is narrower closer to the bowl, the stem then follows the flare out of the shank. I was really struggling with the stain on this as the wood did not seem to want to take it and even the slightest buffing would remove A LOT!

Overall I'm extremely happy for this being my 2nd pipe. I am open to pointers and suggestions. I am using a washer motor for a wheel to sand and buff, I have a drill press from the 80s and a drill powered bandsaw with a warped blade, hand files, and sand paper. So if there is anything glaringly problematic in this pipe, please let me know so I can keep it in mind for my next one. I think I will be making my 3rd one for myself this time