I'm still impressed though.

Todd

I got fuchi_jeg's pipe a few days ago and finally had time to smoke it. It's a nice little pipe. There are quite a few scratches on the stem, particularly near the button. The stem/shank junction also has a gap around the edges. The draw is adequate, but could be just a hair more open. The button could also stand to be thinner and have a slightly lower profile. All that being said, the shaping on this pipe is really great. It's very symmetrical; the diamond shank is really well done and looks perfect. Other than the aforementioned gap, the shank shape transitions very nicely into the stem shape. And the stem is very, very well shaped. Really crisp lines and, despite the small scratches, a very shiny finish. The stummel is well finished and doesn't seem to have any scratches that were overlooked. The pipe smokes really well, with no whistles or gurgles. Thanks fuchi_jeg, it's a pleasure to smoke. Nice work!fuchi_jeg wrote:or just rip off some dunhill shape and make it look like a cheap peterson. I have to try to make the stem/shank fit better, but I think this is my PITH pipe. I have some touching up to do tomorrow. I will post in the gallery when it is totally finished.

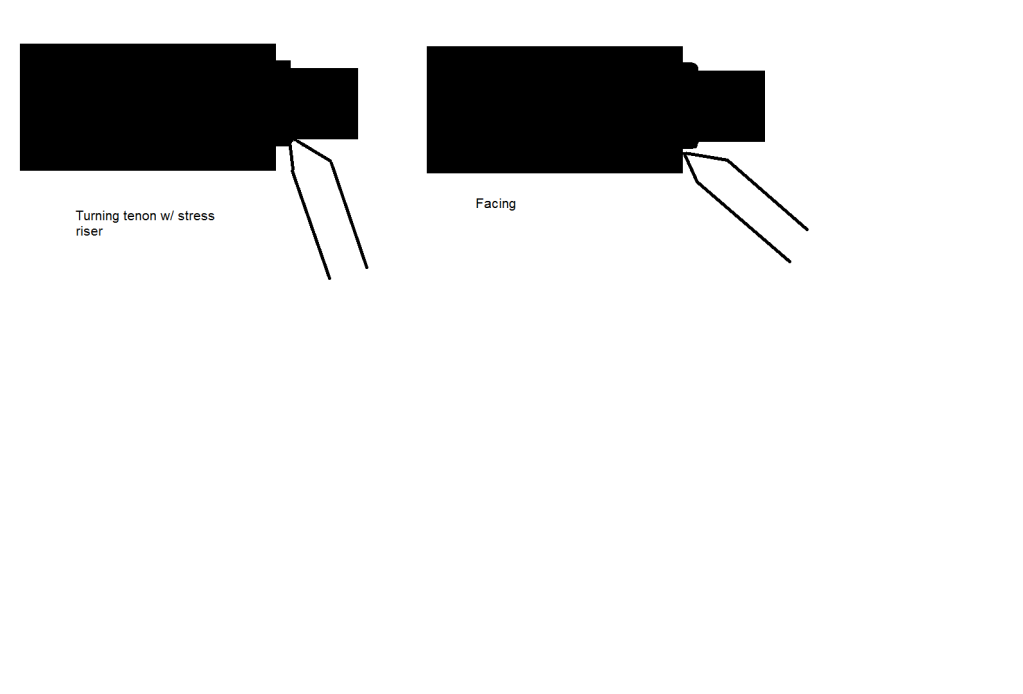

Even on a metal lathe you won't get a perfectly square shoulder, nor should you attempt to. The radius on the shoulder there acts as a strain relief in the event that the pipe is dropped, and when the tenon/stem junction is under any sort of stress. A sharp, square shoulder will actually promote the tenon snapping off by concentrating all the forces in that one tiny area, while a radiused shoulder spreads the load out over a comparatively huge area.fuchi_jeg wrote:Thanks Tim. I spent quite a long time trying to make the junction fit better, but it ended up just shifting the gap to a different area. It was my first integral tenon and I hadn't quite figured out how to square the shoulder on a wood lathe.

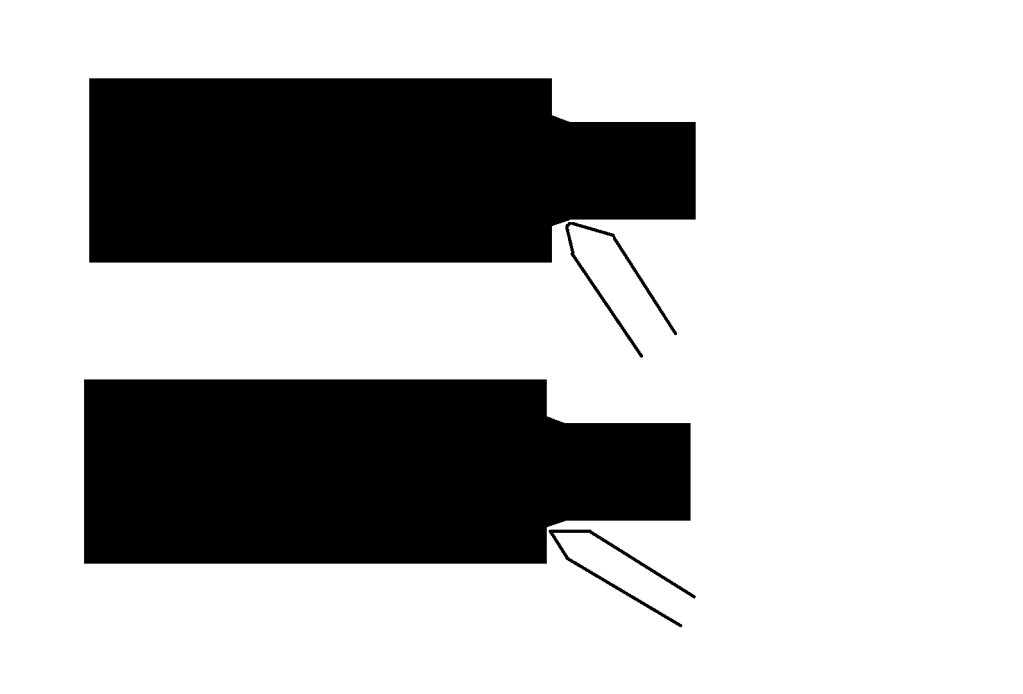

This is something I've been working on as well. I've been going over pipes in my collection and squinting at tenons online. Does this diagram sum it up correctly?KurtHuhn wrote:Even on a metal lathe you won't get a perfectly square shoulder, nor should you attempt to. The radius on the shoulder there acts as a strain relief in the event that the pipe is dropped, and when the tenon/stem junction is under any sort of stress. A sharp, square shoulder will actually promote the tenon snapping off by concentrating all the forces in that one tiny area, while a radiused shoulder spreads the load out over a comparatively huge area.

To solve the problem of the shoulder interfering with stem fitment, just countersink the mortis to fit the shoulder. A 60-degree countersink will usually do the job as long as the shoulder is a reasonable size.