Turning long shanks...

Turning long shanks...

Anyone have any experience turning long shanks? Have any trouble with it? Any tips?

- KurtHuhn

- Site Admin

- Posts: 5326

- Joined: Thu Nov 23, 2006 8:00 pm

- Location: United States/Rhode Island

First I drill the mortis and airway, then I use a 60-degree live center in the tailstock to steady the block.shank as I turn it. I usually use a bowl gouge, also called a fingernail gouge, to turn the shank to rough size. Then I use a skew chisel as a scraper to finish off the shank. I leave the end, near the cap, a little proud of the stem diameter. That way I can blend the taper in.

Agree with Kurt - do the thing "between centers" in order to support it well. If you are doing a really thin shank, sometimes a workpiece will develop a bit of a harmonic bounce on the lathe if you are too aggressive with the tools. There is a dangerous but effective method of controlling that wobble with a hand on the backside of the workpiece, but combined with a gouge, it gets a bit tricky.

Safer, as a finishing "move", you can get into using a file, which has the advantage of being long and flat and tends to take any bumps out of your "straight" lines. Hold a file at about 45 degrees from perpendicular, and just gently run it up and down the the shank, being careful NOT to catch the rest of the spinning stummel (which is to say, near the bowl, you need to get back to perpendicular). You can do this with the tool rest out of the way completely, and this allows you a finger or two to prevent the piece from bouncing at all as well.

Safer, as a finishing "move", you can get into using a file, which has the advantage of being long and flat and tends to take any bumps out of your "straight" lines. Hold a file at about 45 degrees from perpendicular, and just gently run it up and down the the shank, being careful NOT to catch the rest of the spinning stummel (which is to say, near the bowl, you need to get back to perpendicular). You can do this with the tool rest out of the way completely, and this allows you a finger or two to prevent the piece from bouncing at all as well.

If you have a metal lathe large enough to turn stummels, you should have better control on turning a cylindrical shank once you get the speed of rotation, infeed and longitudinal speed correct, as opposed to freehand turning on a wood lathe. HSS or uncoated carbide toolbits should work best for turning wood.

Regards,

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Frank.

------------------

Grouch Happens!

People usually get the gods they deserve - Terry Pratchett

Since this is a forum of sharing... This is how I cut a straight shank. I can get about 4 or 5 inches cut (I'd have to go measure the depth to be sure), but they definitely make short work of it.

Kim Kendall

http://www.PenguinBriar.com/

http://www.PenguinBriar.com/

-

pennsyscot

- Posts: 223

- Joined: Thu Jun 26, 2008 5:03 pm

- Location: pennsylvania USA

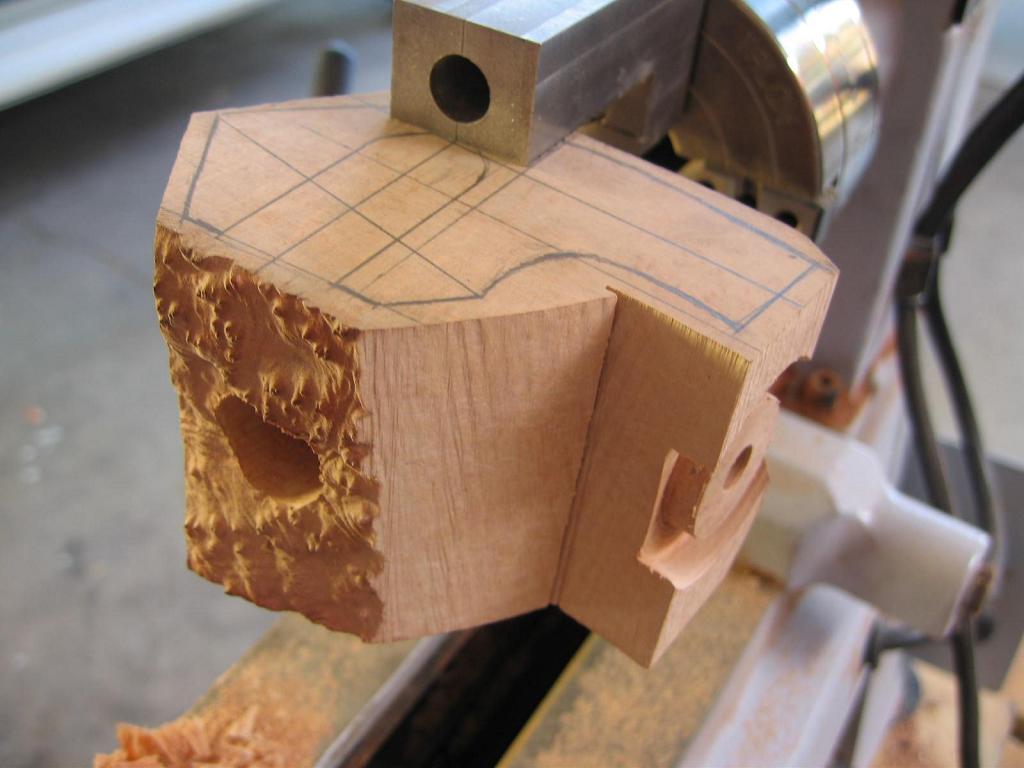

When the block is set up in the lathe - when drilling the airhole & mortise, just pop the cutter into the tailstock chuck and do a plunge cut. Here is a pic of an example where I used the cutter. I only went in about 1/4" just to create a reference (and with a larger diameter cutter) but you can see what it does.

Kim Kendall

http://www.PenguinBriar.com/

http://www.PenguinBriar.com/