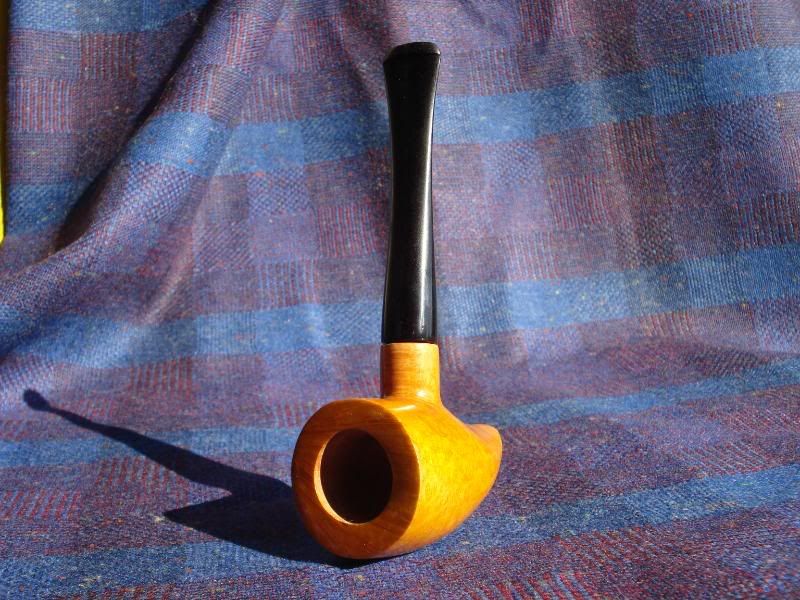

The rounding over of the stem "shoulder" is typically a sign that the stem was buffed without being attached to the shank, but it could also be that your block and sandpaper routine isn't working right.

Make sure your block face and the hole in it are absolutely perpendicular. I assume you have drill press. To ensure flatness, I've heard of using glass or granite. Personally, I use a drill bit index, if I have to. Also, it may not be your stem or only your stem that isn't perfectly perpendicular to the tenon/mortise - it could be the shank too, depending on your tools and procedures. What I do (did, now that I got a metal lathe

) is spray adhesive the sandpaper to the drill index and sandwich it between the shank and stem with the paper toward the shank (or stem) and twist the index. With the index sandwiched in there, you can kind of see where the high points are and whether it is the stem or the shank. Be forewarned, it takes a delicate hand and focused eye to do it right. It's easy to make a worse mess of it.