Craig,

Thanks, too bad I couldn't send this block on an international tour and have every one sketch on it.

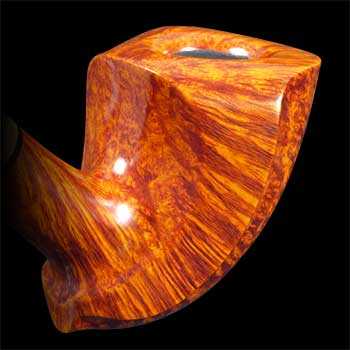

As I understand you think the pipe should be rotated on that side so the grain is running top to bottom. If so, do you think that the other three sides would mostly be birdseye? Possibly I am just hung up on the Birdseye front and the shape. Is there a particular shape or pipe you see also?

Another thing, I have seen sketches where the pipe is small in relation to the size of the block and half the block is not even used, as a newbe and frugal yankee I was shocked. It took a while for it to sink in that he had selected the best grain in the block and a shape that would take advantage of it.

As for the grain running across, I had not even given it consideration and

probably should have (thanks for pointing it out).

I did sand the bark off and will probably have to go a bit deeper to see if

the front does indeed have a nice birdseye pattern. It is almost to the front and looks to be a bit "bald", a little naked in areas, not quite what I had first envisioned. So my first impression might be totally off.

I have noted that is several of the pick-axe, elephant's foot (don't know how that name evolved) have one or two sides are cross grained with excellent birdseye on the front and back. This is kind of what I had in mind.

As you say Beauty is in the eye of the beholder..., but well trained eyes will see more of it. Thanks again. BTW this is my first (non-kit) block, so the decision process is new to me.